Biofuels Biomass-Renewable Energy Sources

Biofuels that have similar properties to and can be used for the same purposes as petroleum distillate fuels include biodiesel, renewable diesel, renewable jet/aviation fuel, and renewable heating oil. Along with fuel ethanol, they qualify for the U.S. Renewable Fuel Standard (RFS) Program and may also qualify for state government fuel standards and programs.[1]

Bioenergy is a source of energy from the organic material that makes up plants, known as biomass. Biomass contains carbon absorbed by plants through photosynthesis. When this biomass is used to produce energy, the carbon is released during combustion and simply returns to the atmosphere, making modern bioenergy a promising near zero-emission fuel.[2]

Modern bioenergy is the largest source of renewable energy globally today, accounting for 55% of renewable energy and over 6% of the global energy supply. The Net Zero Emissions by 2050 (NZE) Scenario sees a rapid increase in the use of bioenergy to displace fossil fuels by 2030. The use of modern bioenergy has increased on average by about 3% per year between 2010 and 2022 and is on an upward trend. More efforts are needed to accelerate modern bioenergy deployment to get on track with the NZE Scenario, which requires deployment to increase by 8% per year between 2022 and 2030, while simultaneously ensuring that bioenergy production does not incur negative social and environmental consequences. [2]

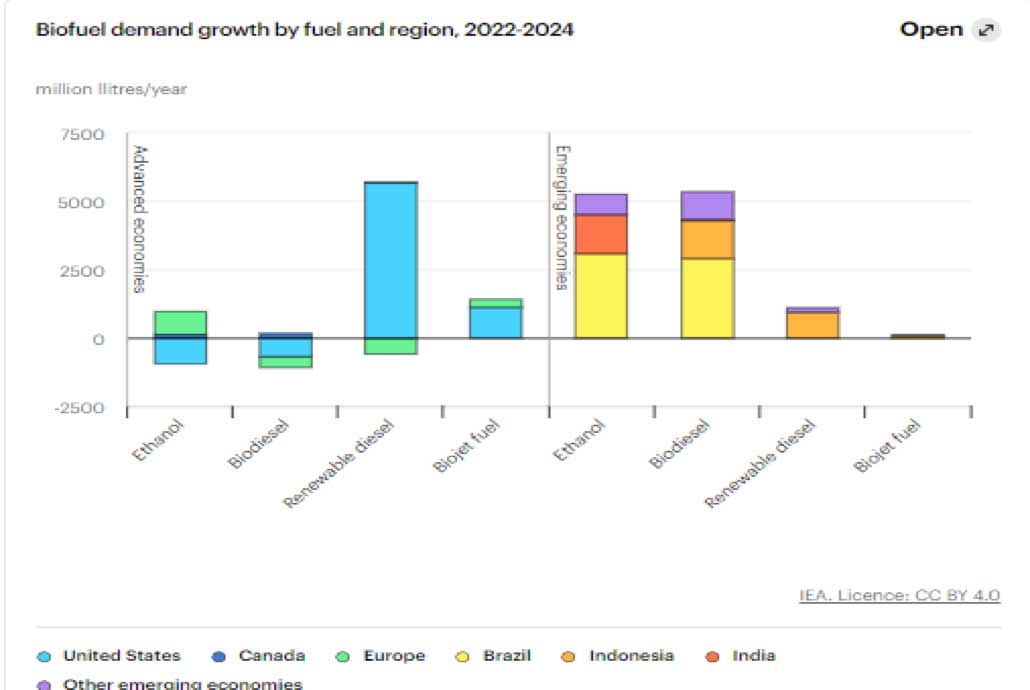

Emerging markets to lead growth in 2023-2024[2]

Energy security returned as a primary rationale for expanding biofuel policies last year. Similar to the forecast before Russia’s invasion of Ukraine, our updated forecast expects 11% (18,000 million litres) of new demand by 2024, supported by policies with energy security objectives. However, as of 2022, only a few markets are actively trying to accelerate deployment by 2024. In advanced markets, new policies are not likely to influence production until after 2024, and high prices, feedstock concerns and technical constraints limit additional growth beyond our 2021 forecast. [2]

Nearly two-thirds of biofuel demand growth will occur in emerging economies, primarily India, Brazil and Indonesia. All three countries have ample domestic feedstocks, additional production capacity, relatively low production costs and a package of policies they can leverage to increase demand. Policies in all three countries are also rooted in energy security considerations, as greater biofuel use will offset some oil imports. India imported 87% of its crude oil supply and Indonesia’s net imports made up 20% of supply in 2021. Brazil is a net crude exporter but still imported 19% of its gasoline and diesel in 2021. [2]

Biodiesel

Biodiesel is one of the first biofuels: Rudolf Diesel, the inventor of the diesel engine in 1897, experimented with using vegetable oil as fuel in his engines. The fuel made from vegetable oils and animal fats that we call biodiesel today is named after him because it is mostly used in diesel engines (as is petroleum diesel fuel). Biodiesel meets the American Society for Testing and Materials (ASTM) specification D6751 and is approved for blending with petroleum diesel/distillate. Biodiesel is produced by transesterification of vegetable oils and animal fats. Vegetable oils (mainly soybean oil) are the main feedstocks for U.S. biodiesel production. Other major U.S. biodiesel feedstocks include animal fats from meat processing plants and used (recycled) cooking oil and yellow grease from restaurants. Rapeseed oil, sunflower oil, and palm oil are major feedstocks for biodiesel production in other countries. Algae are potential sources of biofuels. Algae contain pockets of fat that help keep them afloat that can be collected and processed into biofuels. The feedstocks used for biodiesel production can affect the physical properties and uses of biodiesel. [1]

Biodiesel is a liquid fuel produced from renewable sources, such as new and used vegetable oils and animal fats and is a cleaner-burning replacement for petroleum-based diesel fuel. Biodiesel is nontoxic and biodegradable and is produced by combining alcohol with vegetable oil, animal fat, or recycled cooking grease. Like petroleum-derived diesel, biodiesel is used to fuel compression-ignition (diesel) engines. Biodiesel can be blended with petroleum diesel in any percentage, including B100 (pure biodiesel) and, the most common blend, B20 (a blend containing 20% biodiesel and 80% petroleum diesel). [3]

Ethanol

Ethanol (CH3CH2OH) is a renewable fuel that can be made from various plant materials, collectively known as “biomass.” Ethanol is an alcohol used as a blending agent with gasoline to increase octane and cut down carbon monoxide and other smog-causing emissions. The most common blend of ethanol is E10 (10% ethanol, 90%) gasoline and is approved for use in most conventional gasoline-powered vehicles up to E15 (15% ethanol, 85% gasoline). Some vehicles, called flexible fuel vehicles, are designed to run on E85 (a gasoline-ethanol blend containing 51%–83% ethanol, depending on geography and season), an alternative fuel with much higher ethanol content than regular gasoline. Roughly 97% of gasoline in the United States contains some ethanol. Most ethanol is made from plant starches and sugars—particularly corn starch in the United States—but scientists are continuing to develop technologies that would allow for the use of cellulose and hemicellulose, the non-edible fibrous material that constitutes the bulk of plant matter. The common method for converting biomass into ethanol is called fermentation. During fermentation, microorganisms (e.g., bacteria and yeast) metabolize plant sugars and produce ethanol. [3]

Renewable diesel and other biofuels

Renewable diesel and other (non-fuel ethanol) biofuels and bio intermediates can be produced from nearly any biomass feedstock, including those used for biodiesel production, through a variety of processes, such as: [1]

- Hydrotreating

- Gasification

- Pyrolysis

- Other biochemical and thermochemical technologies

Renewable diesel is similar to biodiesel but with important differences. Renewable diesel is a hydrocarbon that is chemically equivalent to petroleum diesel and can be: [1]

- Used as a drop-in biofuel

- Transported in petroleum pipelines

- Sold at retail stations with or without blending with petroleum diesel

Renewable diesel production uses a hydrogenation process rather than the esterification process used to produce biodiesel. Because renewable diesel is a drop-in fuel, it meets ASTM D975 specifications for petroleum diesel and can be seamlessly blended, transported, and even co-processed with petroleum diesel. Most renewable diesel is hydrogenation-derived renewable diesel (HDRD) or hydroprocessed esters and fatty acids (HEFA) produced by hydrogenation of triglycerides, a similar process used for desulfurizing petroleum diesel. So, existing petroleum refineries can be converted to renewable diesel production with only modest changes. However, hydrotreating renewable feedstocks requires significantly more hydrogen than desulfurizing diesel, and the source of the hydrogen could affect whether or not the renewable diesel can meet national or state standards for biofuels. Other methods can be used for renewable diesel production, such as gasification and pyrolysis. Renewable heating oil is similar to renewable diesel fuel but meets ASTM D396 for fuel oils. Renewable jet fuel may be called sustainable aviation fuel (SAF), alternative jet fuel (AJF), or biojet depending on the context or fuel standard under which it is used. Renewable jet fuel meets ASTM D7566, which allows up to a 50-50 blend of biomass-derived blending components and petroleum jet fuel. Other non-fuel ethanol biofuels include renewable naphtha, renewable gasoline, renewable propane (a by-product of renewable diesel and SAF production), and other emerging biofuels. Another aviation biofuel that is being tested for use is alcohol-to-jet (ATJ) (or ethanol-to-jet [ETJ]). [1]

Modern bioenergy does not include the traditional use of biomass in developing countries and emerging economies for cooking and heating with open fires or simple stoves, which badly impairs human health and the environment. The use of these traditional biomass will fall to zero by 2030 in the Net Zero Scenario to achieve the UN Sustainable Development Goal 7 on Affordable and Clean Energy.

[1] https://www.eia.gov/energyexplained/biofuels/biodiesel-rd-other-basics.php